Advantages of PC Hollow Sheet Extrusion

Hey there, curious reader! Today, we’re diving into the fascinating world of polycarbonate extrusion, specifically focusing on the advantages of PC hollow sheet extrusion. Whether you’re a DIY enthusiast, a construction professional, or just someone eager to learn, this article will break down everything you need to know about this cool technology in a super easy-to-understand way. Select the best pc hollow sheet extrusion line.

What is PC Hollow Sheet Extrusion?

Alright, let’s start with the basics. PC stands for polycarbonate, which is a super strong, lightweight plastic material. When we talk about extrusion, we’re referring to a process where this polycarbonate is melted and shaped into sheets. The “hollow” part? It means these sheets have a unique structure with hollow spaces inside, kinda like a honeycomb. This gives them some pretty nifty benefits, which we’ll explore in just a bit.

Understanding Polycarbonate Material

Polycarbonate is a thermoplastic known for its strength and resilience. Unlike other plastics, it maintains its integrity under high impact and temperature conditions. This makes it an ideal choice for various applications where durability is a key factor. Furthermore, its lightweight nature means it can be used in projects where reducing load is essential without compromising on strength.

The Extrusion Process Explained

The extrusion process is a fascinating transformation where raw polycarbonate pellets are turned into versatile sheets. It begins with feeding these pellets into an extrusion machine, where they are heated to a molten state. This liquid form is then shaped through a mold to create hollow sheets. The precision of this process ensures the sheets have consistent thickness and quality.

The Unique Structure of Hollow Sheets

The hollow structure of these sheets is not just for aesthetics; it serves multiple functional purposes. The air pockets within the sheets act as insulators, providing thermal benefits. Additionally, this design reduces the material used, making the sheets lighter and more cost-effective. This honeycomb-like configuration is what sets PC hollow sheets apart from solid alternatives.

Why Choose PC Hollow Sheets?

So, why should you even care about PC hollow sheets? Well, there are tons of reasons! Let’s take a look at some of the top advantages.

Lightweight Yet Strong

PC hollow sheets are like the superheroes of the plastic world. They’re super strong and durable but don’t weigh a ton. Imagine having the strength of steel but being able to carry it with one hand. That’s what these sheets are like! This makes them perfect for projects where weight matters, like roofing or greenhouses.

Strength Without the Weight

The unique composition of PC hollow sheets allows them to offer a remarkable strength-to-weight ratio. This means that while they are incredibly robust, their lightweight nature makes them easy to transport and install. This feature is particularly beneficial in construction, where reducing the load on structural elements is crucial.

Versatility in Application

Thanks to their lightweight and strong properties, PC hollow sheets are used in a wide range of applications. From agricultural projects to architectural designs, they provide a reliable option that doesn’t compromise on quality. Their ability to be molded into different shapes and sizes further enhances their versatility.

Comparison with Other Materials

When compared to traditional materials like glass or solid polycarbonate, hollow sheets stand out due to their reduced weight and enhanced flexibility. This makes them a more practical choice in scenarios where ease of handling and installation are priorities, without sacrificing durability.

Great Insulation Properties

One of the coolest things about PC hollow sheets is their ability to insulate. Thanks to their hollow structure, they trap air inside, which helps keep things warm in the winter and cool in the summer. So, whether you’re building a greenhouse or an office partition, these sheets can help save on energy bills!

Thermoregulation Benefits

The hollow spaces within the sheets act as natural insulators, maintaining consistent temperatures inside structures. This thermoregulation reduces the need for additional heating or cooling systems, leading to energy efficiency and cost savings over time.

Energy Efficiency

By minimizing heat transfer, PC hollow sheets contribute to significant energy savings. Whether used in residential or commercial buildings, they reduce the dependency on artificial climate control, thus lowering energy consumption and utility bills.

Environmental Impact

Utilizing PC hollow sheets contributes to a reduction in carbon footprint. Their energy-efficient properties mean less reliance on fossil fuels for heating and cooling, promoting a more sustainable and eco-friendly approach to building and design.

High Impact Resistance

Ever worried about something breaking easily? With PC hollow sheets, that’s not a concern. These sheets can withstand impacts way better than glass and many other materials. So, if you’re in an area prone to hailstorms or just have clumsy hands, these are your go-to.

Resilience Under Pressure

PC hollow sheets are engineered to withstand high levels of impact without shattering. This makes them an excellent choice for areas prone to harsh weather conditions, such as hailstorms or strong winds. Their resilience ensures long-term durability and reduced maintenance costs.

Safety Considerations

In environments where safety is paramount, such as schools or public buildings, the impact resistance of these sheets provides peace of mind. Unlike glass, which can break into sharp shards, polycarbonate sheets remain intact, reducing the risk of injury.

Applications in High-Risk Areas

In industrial settings or areas exposed to potential hazards, the robust nature of PC hollow sheets offers a reliable protective solution. They can serve as protective barriers, safeguarding both people and property from unforeseen impacts.

UV Protection

Nobody likes sunburn, and neither do your projects. PC hollow sheets offer excellent UV protection, shielding what’s inside from harmful rays. This means they won’t yellow or degrade as quickly as other materials when exposed to sunlight.

Protection Against UV Degradation

One of the standout features of PC hollow sheets is their ability to block harmful UV rays. This protection prevents the sheets from yellowing or becoming brittle over time, ensuring longevity and preserving their aesthetic appeal.

Preserving Interior Environments

By filtering out UV radiation, these sheets help protect the interior contents of a building. Whether it’s furniture, artwork, or plants, they remain safe from the damaging effects of prolonged sun exposure, maintaining their condition and value.

Prolonged Lifespan

The UV-resistant properties of PC hollow sheets contribute to their extended lifespan. By mitigating the effects of sun exposure, they maintain their structural integrity and appearance, reducing the frequency of replacement and long-term costs.

Easy to Install and Handle

Because they’re lightweight, PC hollow sheets are super easy to handle and install. You don’t need a whole crew to get them up and running. Plus, they can be cut to size with just a basic toolkit. Talk about convenience!

Simplified Installation Process

The ease of cutting and fitting PC hollow sheets means that installations can be completed quickly and efficiently. This is particularly advantageous for DIY projects or when time constraints are a concern. The reduced need for specialized tools or labor makes the process accessible to a broader audience.

Cost-Effective Solutions

With the ease of installation comes cost savings. Reduced labor costs and shorter project timelines mean that using PC hollow sheets is not only convenient but also economical. This affordability makes them an attractive option for budget-conscious projects.

Minimal Maintenance Requirements

Once installed, PC hollow sheets require minimal upkeep. Their durability and resistance to environmental factors mean they maintain their condition with little intervention. This low maintenance requirement adds to their overall cost-effectiveness and appeal.

The Extrusion Technology Behind It

Now, you might be wondering, how do we make these awesome sheets? Enter the world of extrusion technology.

The Extrusion Process

The process starts with polycarbonate pellets being fed into an extrusion machine. Here, they’re heated until they melt into a gooey, liquid form. This molten polycarbonate is then pushed through a specially designed mold, shaping it into the hollow sheets we know and love.

From Pellets to Sheets

The journey from raw polycarbonate pellets to finished sheets is a marvel of modern engineering. The controlled heating and shaping process ensures that the material properties are maintained, resulting in high-quality end products that meet exacting standards.

Precision in Design

The molds used in extrusion are meticulously designed to create sheets with precise dimensions and characteristics. This attention to detail ensures uniformity across all sheets, which is essential for applications where consistency is critical.

Innovations in Extrusion Technology

Advancements in extrusion technology continue to enhance the efficiency and capabilities of the process. Innovations such as improved temperature control and mold design have expanded the possibilities for PC hollow sheet applications, making them even more versatile and reliable.

Cooling and Cutting

After shaping, the sheets are cooled down to solidify. Once they’re nice and firm, they’re cut into the desired lengths. And voila! You’ve got yourself some top-quality PC hollow sheets.

The Cooling Phase

Cooling is a crucial step in the extrusion process, as it solidifies the molten polycarbonate into a stable form. The cooling rate must be carefully controlled to prevent warping or other defects, ensuring the sheets retain their desired properties.

Precision Cutting Techniques

Once cooled, the sheets are cut to specified lengths using precision cutting equipment. This step is critical for ensuring that the sheets meet the exact dimensions required for their intended application, minimizing waste, and maximizing efficiency.

Quality Assurance Measures

Throughout the cooling and cutting stages, rigorous quality checks are implemented to ensure the sheets meet all necessary standards. This commitment to quality ensures that every sheet delivered is fit for purpose and free from defects.

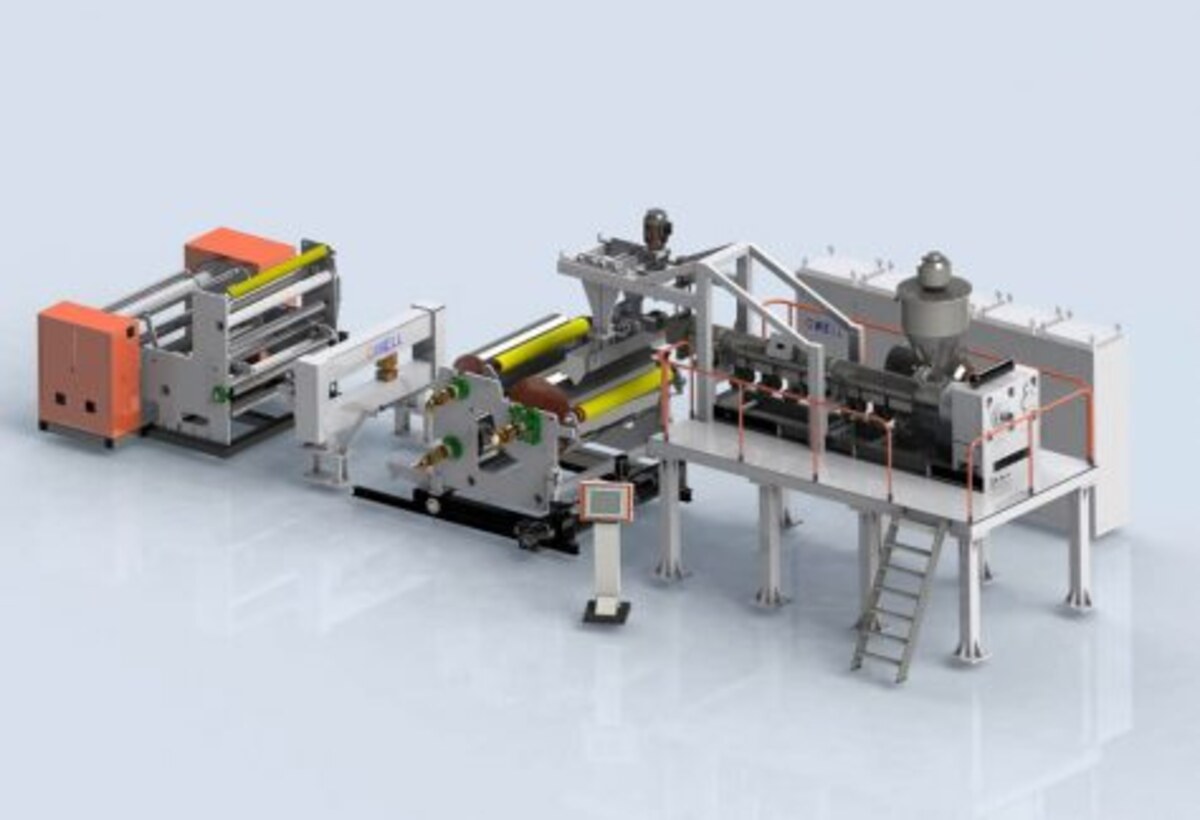

The Role of the Extrusion Line

The extrusion line is like a mini factory dedicated to producing these sheets. It includes all the machinery needed for heating, shaping, cooling, and cutting. A well-designed extrusion line ensures that every sheet comes out perfect, with consistent quality and dimensions.

Components of the Extrusion Line

An extrusion line is a complex assembly of machinery that works seamlessly to produce PC hollow sheets. Key components include the extruder, mold, cooling system, and cutting equipment. Each element plays a vital role in the overall production process.

Ensuring Consistency and Quality

The design and operation of the extrusion line are critical for maintaining product consistency. Advanced monitoring systems and automated controls help in achieving uniformity in sheet thickness and quality, reducing the likelihood of defects.

Efficiency and Productivity

Modern extrusion lines are designed to maximize efficiency and productivity. They incorporate the latest technology to streamline operations, reduce energy consumption, and increase output, making the production of PC hollow sheets both cost-effective and sustainable.

Applications of PC Hollow Sheets

So, where exactly can you use these handy sheets? The possibilities are almost endless, but here are a few popular applications:

Greenhouses

Thanks to their insulation and UV protection, PC hollow sheets are perfect for greenhouses. They help maintain an optimal temperature for plant growth while protecting them from harsh weather.

Creating Optimal Growing Conditions

PC hollow sheets provide the ideal environment for plant growth by maintaining consistent internal temperatures. This stability is crucial for extending the growing season and maximizing crop yields, making them a preferred choice for commercial and hobbyist gardeners alike.

Protection from Environmental Extremes

The durability and UV protection offered by PC hollow sheets shield plants from harsh weather conditions, such as heavy rain or intense sunlight. This protection ensures that plants thrive in a controlled environment, regardless of external factors.

Enhancing Energy Efficiency

The insulating properties of these sheets reduce the need for supplemental heating or cooling in greenhouses. This energy efficiency not only lowers operational costs but also contributes to sustainable agricultural practices, making them an eco-friendly choice for growers.

Skylights and Roofing

Want to let in natural light without compromising on strength? These sheets are ideal for skylights and roofing. They provide the perfect balance of light transmission and durability.

Maximizing Natural Light

PC hollow sheets excel in allowing natural light to flood into spaces, creating bright and inviting environments. This natural illumination reduces the need for artificial lighting during the day, leading to energy savings and a reduced carbon footprint.

Durable Roofing Solutions

In roofing applications, the strength of PC hollow sheets ensures long-lasting protection against the elements. Their impact resistance and weatherproof nature make them a reliable choice for both residential and commercial buildings.

Aesthetic and Functional Benefits

Beyond their practical advantages, PC hollow sheets contribute to the aesthetic appeal of structures. Their sleek, modern appearance enhances architectural designs, while their functional benefits make them a smart choice for a variety of roofing applications.

Sound Barriers

Need to keep things quiet? PC hollow sheets can act as effective sound barriers, making them great for use along highways or in industrial areas.

Reducing Noise Pollution

The acoustic properties of PC hollow sheets make them effective at dampening noise, creating quieter environments in urban or industrial settings. This noise reduction is essential for improving the quality of life for residents and workers in these areas.

Versatile Applications

Whether used in transportation infrastructure or as partitions in industrial facilities, PC hollow sheets offer versatile solutions for noise control. Their lightweight and durable nature makes them easy to install and maintain, providing long-term benefits.

Enhancing Acoustic Comfort

By minimizing unwanted noise, PC hollow sheets contribute to more comfortable and productive environments. This acoustic comfort is particularly valuable in settings such as offices, schools, or residential areas, where reducing noise is a priority.

Partitions and Interior Design

For those looking to add a modern touch to interiors, these sheets can be used for partitions and decorative elements. They’re easy to work with and can be customized to fit any design vision.

Modern Interior Solutions

The versatility of PC hollow sheets makes them ideal for contemporary interior design applications. Their sleek appearance and customizable nature allow for creative design solutions, from partitions to decorative features.

Easy Customization

PC hollow sheets can be easily cut and shaped to fit specific design requirements. This customization enables designers and architects to create unique and innovative spaces that reflect individual styles and preferences.

Combining Functionality and Style

In addition to their aesthetic appeal, PC hollow sheets offer practical benefits such as durability and ease of maintenance. This combination of form and function makes them a popular choice for both commercial and residential interior design projects.

Tips for Working with PC Hollow Sheets

Thinking about starting a project with these sheets? Here are some handy tips to keep in mind:

- Cut with Care: Use a fine-toothed saw for clean cuts. Always measure twice before cutting to avoid mistakes.

- Seal the Edges: To prevent moisture buildup inside the hollow spaces, seal the edges with clear tape or a compatible sealant.

- Support Properly: Ensure that you provide adequate support when installing, especially for larger sheets, to prevent sagging.

Cutting Techniques

When working with PC hollow sheets, precision is key. Using the right tools, such as a fine-toothed saw, ensures clean and accurate cuts. Always double-check measurements to minimize waste and avoid costly errors.

Edge Sealing

Sealing the edges of PC hollow sheets is essential to prevent moisture ingress and maintain their insulating properties. Clear tape or compatible sealants can be used to effectively seal edges, prolonging the sheets’ lifespan and performance.

Proper Support and Installation

Adequate support is crucial to prevent sagging, especially for larger installations. Proper framing and support structures ensure that the sheets remain stable and functional over time, maintaining their aesthetic and practical benefits.

Conclusion

And there you have it! PC hollow sheet extrusion is an amazing technology that offers numerous advantages, from strength and insulation to ease of installation and versatility. Whether you’re sprucing up your greenhouse, adding a skylight, or designing a modern interior, these sheets have got you covered.

We hope you found this guide helpful and feel inspired to tackle your next project with confidence. Happy building!

Read also: The Way to Maximize Chat GPT Free of Charge Usage

Recent Posts

The Art of Healing: Katherine McCann’s Journey

Katherine McCann's journey began with a deep-rooted passion for art and a desire to make…

Understanding the Alexistogel Lottery System

The allure of lotteries has captivated people for centuries, promising the tantalizing dream of instant…

Understanding Betting Predictions: A Comprehensive Guide

Gambling smart isn’t just about luck—it’s about using data, insight, and tested methods to tilt…

How to Choose the Right IPTV Service

In this article, we will guide you through the critical factors to consider when selecting…

Maximize Your WoW Retail Leveling Boost

Before diving into optimization strategies, it's essential to understand what a WoW Retail Leveling Boost…

How to Compare Moving Company Quotes

Before diving into the comparison, it's essential to understand what a moving quote is. Essentially,…